HP partners with Parmatech

September 11, 2018 | Tuesday | News

Parmatech is a world leader in metal injection molding and has been a metals manufacturing pioneer for more than 40 years, specializing in producing low-cost, high-volume metal parts for the medical and industrial sectors.

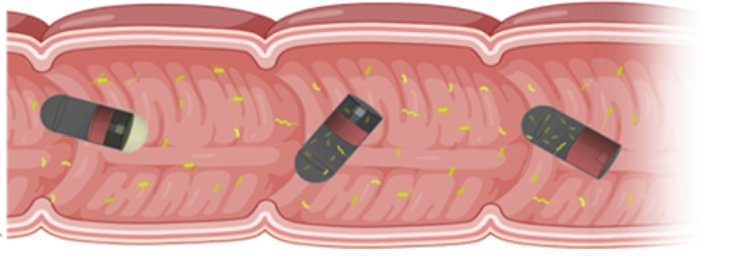

Representative Image

At the 2018 International Manufacturing Technology Show (IMTS), HP Inc. launched HP Metal Jet, the world’s most advanced 3D printing technology for the high volume manufacturing of production-grade metal parts. Providing up to 50 times more productivity at a significantly lower cost than other 3D printing methods, HP Metal Jet is being deployed by manufacturing leaders GKN Powder Metallurgy and Parmatech for the factory production of final parts. Customers placing orders include global stalwarts Volkswagen and Wilo and innovative vertical market leaders such as Primo Medical Group and OKAY Industries.

As part of its mission to transform the way the world designs and manufactures, HP has also launched the Metal Jet Production Service, enabling customers around the world to rapidly iterate new 3D part designs, produce final parts in volume, and integrate HP Metal Jet into their long-term production roadmaps.

“We are in the midst of a digital industrial revolution that is transforming the $12 trillion manufacturing industry. HP has helped lead this transformation by pioneering the 3D mass production of plastic parts and we are now doubling down with HP Metal Jet, a breakthrough metals 3D printing technology,” said Dion Weisler, CEO and President, HP Inc. “The implications are huge – the auto, industrial, and medical sectors alone produce billions of metal parts each year. HP’s new Metal Jet 3D printing platform unlocks the speed, quality, and economics to enable our customers to completely rethink the way they design, manufacture, and deliver new solutions in the digital age.”

HP Metal Jet is a groundbreaking, voxel-level binder jetting technology leveraging more than 30 years of HP printhead and advanced chemistries innovation. With a bed size of 430 x 320 x 200mm, 4x the nozzle redundancy and 2x the printbars, and significantly less binder by weight, HP Metal Jet delivers greater productivity and reliability at a low acquisition and operational cost compared to other metals 3D printing solutions. HP Metal Jet will start with stainless steel finished parts, delivering isotropic properties that meet or exceed ASTM and MPIF Standards

Reinventing Healthcare With HP Metal Jet

To serve the medical industry, HP is also partnering with Parmatech, an ATW Company, to expand mass production of Metal Jet parts for customers including OKAY Industries, Primo Medical Group, and others. Parmatech is a world leader in metal injection molding and has been a metals manufacturing pioneer for more than 40 years, specializing in producing low-cost, high-volume metal parts for the medical and industrial sectors.

“HP Metal Jet represents the first truly viable 3D technology for the industrial-scale production of metal parts. Our customers demand extreme performance, quality, and reliability and HP’s advanced technology and heritage of market disruption give us the confidence to deliver beyond expectations,“ said Rob Hall, President of Parmatech. “We are excited to deploy HP Metal Jet in our factories and begin manufacturing complex parts, such as surgical scissors and endoscopic surgical jaws, and new applications and geometries not possible with conventional metal fabrication technologies. HP Metal Jet technology will play a key role in our mission to develop innovative solutions for the unique challenges of our customers.”