IKA launches new batch mill

February 24, 2016 | Wednesday | News | By BioSpectrum Bureau

IKA launches new batch mill

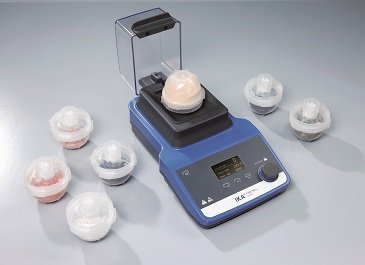

The Tube Mill's versatility is particularly noteworthy

IKA Group launches the TUBE MILL control and the TUBE MILL 100 control that represents a unique product innovation - the world's first batch mill with single-use milling vessels. For the first time, this unit will enable serial testing to be carried out under reproducible, contamination-free conditions.

The single-use milling vessels reduce the cleaning, time and energy that is devoted to the application process. These vessels also prevent cross contamination of the sample material - a major advantage for quality assurance.

The 40 ml and 100 ml capacity milling vessels and hood are made from transparent material, allowing sample milling to be observed during the process itself. With the Tube Mill 100 control larger grinding chambers with a maximum volume of 100 ml (MT 100) can now be used. For sterile applications you can use the sterile disposable grinding chamber MT 40-10 sterile with a stainless steel beater. It reduces soft, medium, hard and brittle materials with a Mohs hardness of up to 5 (manganese or apatite: 5 Mohs).

The unit is easy to operate thanks to the user-friendly, multilingual OLED display and timer function.

The Tube Mill's versatility is particularly noteworthy. The IKA Tube Mill control can be used to process hard and soft, brittle and dry material. In combination with dry ice, it also allows damp, fatty, elastic and fibrous materials to be milled thoroughly.

The wide speed range of this unit equates to processing times that are less than one minute for most samples.

Particular attention was paid to safety in the development of this mill, which only operates if the hood is closed and the milling vessel is connected to the motor and properly secured. If any of these safety features are omitted, an error message is displayed. The milling vessel cannot be opened during the milling process.

A labyrinth seal on the motor prevents dust escaping from the milling vessel and getting into the motor. In case of pollution the coupling of the motor can be removed and cleaned very easily.

The speed is infinitely adjustable from 5,000 to 25,000 l/min. Again, safety is ensured by a combination of an adjustable safety speed and adjustable safety time function. For instance, these features will prevent samples from overheating.

Tests can also be controlled and documented via a USB interface. The latest firmware can be downloaded via the associated interface.

In developing the Tube Mill, IKA was able to draw on 105 years of laboratory technology experience, in addition to the more recent experiences involving the award winning UTTD single-use dispersing system.