Combat-ready for Future Pandemic

March 01, 2022 | Tuesday | Views

Several facets of our great nation were brought forth by the sudden impact of COVID-19. For one, healthcare infrastructure and diagnostics need fundamental changes and strategic direction for future improvement. Vaccinology has, however, written success stories in both development and manufacturing. It also highlighted how public-private partnership can succeed, building on the nation’s earlier success with developing and manufacturing world-class Rotavirus vaccine ROTAVAC, TYPBAR TCV, the innovator Typhoid Conjugate Vaccine among other world-leading vaccines. These challenging times also reaffirmed the growing need to nurture startups in areas of vaccine development and the ever-increasing need for the industry and academia to participate in advancing science.

India had the advantage of two good vaccines to fight the SARS-COV-2 virus and both vaccine companies have to be commended for their contributions during this pandemic. India has placed itself in the upper tier of countries such as the United States and China, where more than two COVID-19 vaccines were manufactured and supplied at scale. Most importantly, Covishield and COVAXIN were available in the quantities required to vaccinate our large nation.

'Necessity is the mother of all inventions' , and adversity can bring out the best or worst in us.

During the early days of the pandemic (January-March 2020), while the nation was grappling to deal with the pandemic, scientists at Bharat Biotech were chalking out its product development strategies towards a self-reliant indigenous vaccine. The company had the option of deploying multiple platforms and vaccine manufacturing technologies such as inactivated, recombinant, viral vectored, etc. Bharat Biotech had invested in these technologies with a significant amount of prior knowledge and expertise in all these platforms including research and development.

Evolution of vaccine research in India

The primary prerequisite for any new vaccine is always safety, safety, safety !. The whole virion inactivated platform technology provided us with the required assurance of safety, with deep expertise to rapidly deploy the technologies required for manufacturing and testing. India was always ahead in its pursuit to research, develop novel vaccines such as the Rotavirus, Typhoid Conjugate, Hepatitis, Zika, Chikungunya, Rabies, among others. Bharat Biotech had existing BSL3 facilities and a vero cell manufacturing platform to manufacture inactivated vaccines. We received the SARS-COV2 strains from Indian Council of Medical Research (ICMR)-National Institute of Virology (NIV)-Pune, and were immediately able to start product development activities. In fact, several developmental activities had already commenced prior to the receipt of strains.

The significant aspect of India’s vaccine was its ability to complete all the preclinical studies and clinical trials required for emergency use approvals. The knowledge on inactivated vaccine platforms led to extensive pre-clinical studies and to conduct safety, immunogenicity, toxicology, and live viral challenges, in multiple animal models including hamsters and primates for the vaccine.

Clinical Trials knowledge is another significant aspect of India’s advancement in vaccine science and establishing its position as a world-leading vaccine developer and manufacturer. COVAXIN has been tested in more than 30,000 subjects (adults & children), for safety, immunogenicity, and efficacy, including, detailed immunogenicity evaluation that was conducted for both humoral and cell-mediated immune responses.

COVAXIN is the most highly studied vaccine in India, in the Indian population, providing a great level of confidence on the safety, efficacy, effectiveness, and duration of immune responses. These detailed clinical evaluation studies have defined COVAXIN as a UNIVERSAL VACCINE with the versatility of the same dosage, that can be administered to adults, and children, for the two-dose primary and booster dose schedules. With approvals from India, 25 other countries, and World Health Organisation (WHO), COVAXIN has become a global vaccine with significant demand from foreign countries. It is one of the few vaccines that have an excellent safety profile, followed by efficacy and cellular immune responses.

Need for self-reliance

The development of COVAXIN was based on knowledge and technologies available in India. Its development has also been instrumental in developing a sustainable ecosystem for vaccine development and R&D in the country.

It leaves behind a sense of accomplishment and self-reliance that the country needs. Institutions such as the NIV-ICMR and Indian Institute of Chemical Technology (IICT), Hyderabad, were instrumental in developing COVAXIN .

While NIV-ICMR provided the strains for the manufacture of COVAXIN, IICT developed the process for synthesis and manufacture for the IMDG molecule used as an adjuvant in COVAXIN. The IMDG molecule licensed from a company in the United States, and the ICMR, both receive royalties as per industry standards. In the process, these institutions have received a rare glimpse and understanding of the R&D and product development process of vaccines, and they will be geared-up for future challenges.

The trail of knowledge does not end at development and licensure, the manufacturing process for COVAXIN is being shared with four companies in India and one in the United States. One of the companies has already absorbed the technology, and started manufacturing and supplies. The IMDG adjuvant molecule is, also, fully manufactured in India - the first adjuvant to be manufactured within India. Hence COVAXIN manufacturing has been 100 per cent indigenised, providing a great amount of vaccine security to our country.

This initiative will result in the manufacturing ecosystem also being activated for vaccines and associated technologies and improve our readiness for future pandemics. Both the biotechnology and chemical-pharmaceutical manufacturing industries have been involved in the manufacture of COVAXIN, both playing their roles.

COVAXIN has created an ecosystem for vaccine development, manufacturing not just at Bharat Biotech, but also around the country. This will surely improve the scientific focus required for a country like ours.

We need to have positive examples of Indian industry and academic institutions showcasing their ability to rise to the challenges during a pandemic.

Most importantly, the financial resources, taxpayers' money, must remain within our country to strengthen our GDP and reduce the drain on our economy.

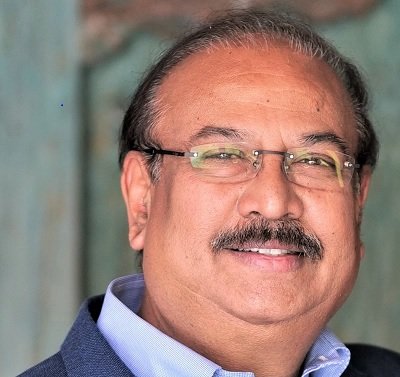

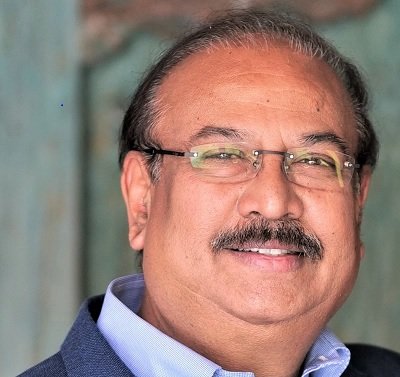

Dr Krishna Ella, Scientist, Serial Entrepreneur and CMD, Bharat Biotech