Romaco to showcase tableting and packaging solutions at P-MEC India

November 06, 2019 | Wednesday | News

P-MEC India will be held in Delhi NCR from November 26 to 28, 2019

Specialist for solid pharmaceuticals

Romaco will take advantage of this year’s P-MEC in Delhi to show a selection of its tableting and packaging solutions. The pharmaceutical machinery manufacturer specialises in engineering technologies for solid pharmaceuticals.

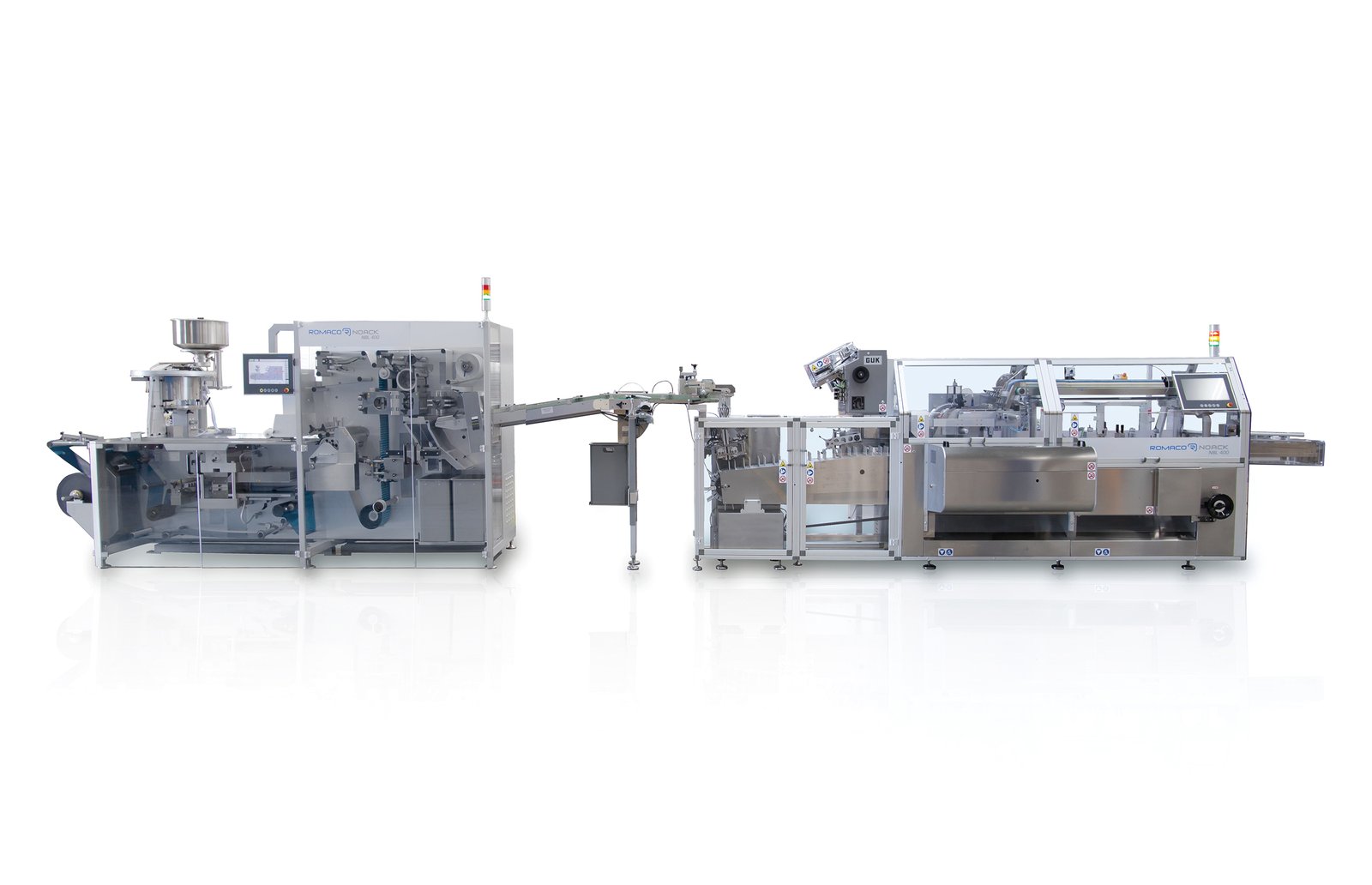

Romaco Noack NBL 400 blister line

Romaco’s new Noack NBL 400 blister line was specifically designed to meet the needs of the Asian pharmaceutical markets. With an output of 400 blisters and up to 300 cartons per minute, this durable line is ideal for medium batch sizes. An integrated solution comprised of a blister machine with rotary sealing and a continuous motion cartoner, it is very easy to use. Machine operators require no specialist technical know-how to work on the blister packaging line and carry out product and format changes. That is why the robust Noack NBL 400 is also recommended as an entry level model for contract packers and pharmaceutical manufacturers seeking to expand their business with solid products. What’s more, nearly all format parts of the Noack 921 blister machine, which is firmly established in the market, are also compatible with Romaco’s new Noack NBL 400 blister line. Here, too, the new blister technology convinces with outstanding versatility and excellent value for money.

Regarding product feeding, the Noack NBL 400 allows very flexible configurations. Tablets and capsules with different specifications can be placed in the blister cavities either individually or using a brush-box feeder. The products can also be fed manually, which is mainly an advantage with sample packs or with very small or clinical batches. The NBL 400 from Romaco Noack is capable of processing any standard thermoformable laminate and can also be employed in the manufacture of aluminium-aluminium blisters. Romaco trusts in BlisterMagic, its software solution, to design the cavity geometries and develop individual packaging layouts. This innovative tool provides a very quick and easy route to customise blister packaging. Users of the Noack NBL 400 blister packaging line also profit from Romaco’s expert support when it comes to packaging designs.

Romaco Kilian KTP 720X: powerful double-sided rotary press

Cool, fast & clean – these three design features of the Romaco Kilian KTP 720X double-sided rotary press are attracting considerable attention among pharmaceutical manufacturers worldwide. “Cool” is a set of measures which enable the temperature in the process area to be maintained at a constant level below 30 °C. Special compression rollers, bolts and bearings are used, for example, to restrict mechanical friction to a minimum. At the same time, the efficient cooling of the V-ring seals and drives prevents unwanted heat. The powerful rotary press is consequently ideal for processing temperature sensitive medications such as Metformin or Ibuprofen. “Fast” denotes the ability to speed up product changes: in order to shorten the retooling and cleaning times, the number of product-contacted format parts has been systematically reduced and access to the various components is now easier than ever.

“Clean” refers to the optimised hygienic design, which improves product quality and makes the process more reliable. The strict separation between the compaction and service areas prevents tablet dust from entering the machine compartment during the production process. The patented punch bellows moreover protect the tablets from contamination with lubricants. With a maximum output of 1,020,000 tablets per hour, the Kilian KTP 720X is classed as a high speed model. The Romaco Kilian additionally impresses with innovative features on the operator side. The HMI panels of this tablet press incorporate zoom and swipe navigation inspired by modern smartphones.

Romaco Macofar MicroMaxX 18 microdosing machine

The Romaco Macofar MicroMaxX 18 microdosing machine processes pharmaceutical powders with different flow properties. The system is equipped with a dual dosing disc which also allows multiple dosing into the same vial. Furthermore, even very small product quantities right down to 20 mg can be dosed precisely. Thanks to an innovative in-line weighing system, one hundred percent weight control is now possible for the first time. The machine achieves a maximum filling speed of 12,000 vials per hour. Up to 18,000 vials an hour are possible in the version with statistical weight control. The Romaco Macofar MicroMaxX 18 can be supplied in different containment designs. Automated processes ensure reliable operation and meet the high cGMP requirements for dosing sterile powders and liquids.