Motorica launches Digital Prosthetics Programme in India

October 09, 2025 | Thursday | News

Motorica has already completed its first successful digital prosthetics cases in India

Motorica, a global medtech company specialising in assistive technologies and medical cybernetics, has officially launched its Digital Prosthetics Programme in India, marking a significant step toward transforming the production and accessibility of prosthetic solutions in the country.

Through this initiative, Motorica leverages 3D scanning, digital modeling, and 3D printing to deliver highly customized mechanical prosthetic arms with unmatched speed and precision.

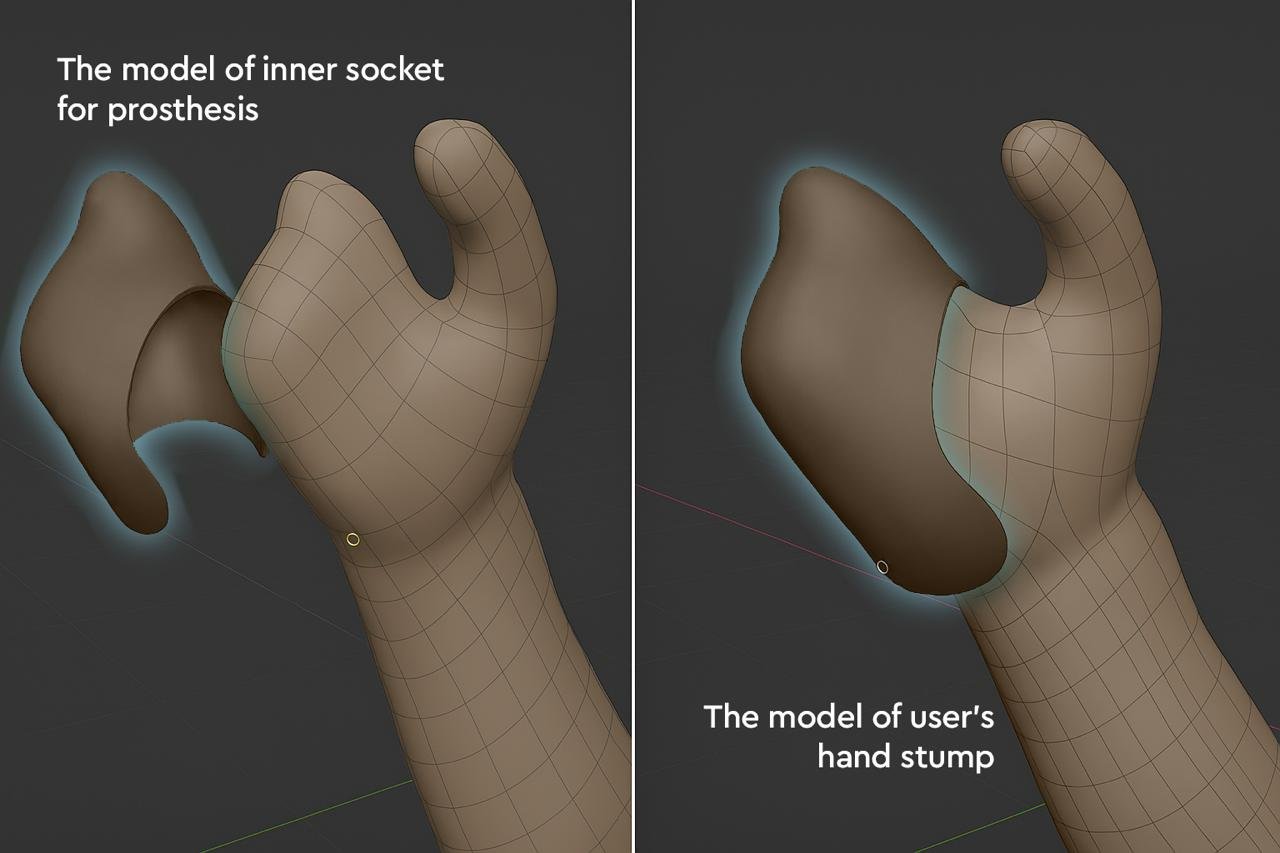

By creating a digital 3D model of the user’s arm, the need for shipping physical molds is eliminated, significantly accelerating production. The final stages of design, printing, and assembly are completed at Motorica’s advanced manufacturing facility in Moscow, Russia ensuring consistent quality. This approach replaces traditional plaster molds with accurate digital data, allowing engineers to refine designs seamlessly using specialised software. Unlike conventional methods that require extensive manual adjustments, digital modeling minimises logistical delays while maintaining the highest standards of accuracy and flexibility.

Motorica has already completed its first successful digital prosthetics cases in India, demonstrating the programme’s real-world impact. To capture the user’s hand geometry, the company utilised photogrammetry, a technique that reconstructs a 3D model from a series of photographs taken with a standard smartphone. This approach eliminates the need for costly scanning equipment, making the process more inclusive and accessible. In these initial cases, partner clinics in India provided photographs of the user’s limb, while Motorica’s engineering team generated the digital model and assembled the prosthesis in record time.