“We are rapidly expanding our capacity at facilities in India to meet existing and future market needs”

July 16, 2021 | Friday | Interviews

A leading global provider of mission-critical products and services to customers in the life sciences, advanced technologies and applied materials industries, US headquartered Avantor is currently at the forefront to help India fight the ongoing COVID-19 crisis. In addition, the company is also playing a pivotal role in collaborating with organizations, both local and global, working on COVID-19 therapies.

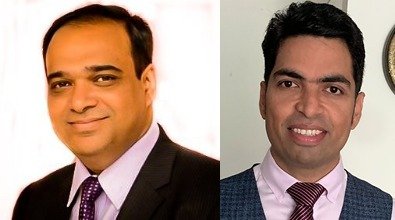

Amit Sehgal, Managing Director, Avantor India (left) and Narayana Rao Rapolu, Vice President, Biopharma, AMEA (Asia, Middle East & Africa) spoke to BioSpectrum about the company’s focus on the Indian market.

Edited excerpts-

How is Avantor currently contributing to the COVID-19 vaccine manufacturing and treatment space in India?

Amit: As a global life sciences company, Avantor provides products and services that play a critical role in pharmaceutical research and development, ranging from process development to commercial scale production. Over the last 18 months alone, our work in pharmaceutical research, scale-up and production has never been more important as we have collaborated with the organizations working on COVID-19 therapies.

Avantor’s products, including cGMP process chemicals, single-use technologies and serum, are present throughout the workflows of vaccines, monoclonal antibodies (mAbs) and related therapies, aiding in getting them to market faster and safer.

Narayana: In vaccine manufacturing, specifically, our understanding of how various chemistries perform in cell culture systems, combined with our portfolio of production chemicals, single-use systems, process chromatography media and final fill products, helps sustain the integrity and activity of COVID-19 vaccines from upstream production or cell-free synthesis to downstream purification process steps, through final fill. Our technical and commercial teams partner with customers in the forefront as solutions are specified for therapies being produced, but the support from our operations and supply chain teams has been equally as critical to ramp capacity and meet the rising demands of our customers in India.

What challenges & new trends do you foresee for the Indian biopharma sector in India?

Narayana: India is a diverse market for pharmaceuticals manufacturing. In recent years, the Indian government has demonstrated strong initiative to promote the pharmaceutical sector, including a $1.3 billion fund to encourage companies to manufacture pharmaceutical ingredients domestically by 2023. The Indian pharmaceuticals market is unique in many ways: branded generics represent more than 70 percent of the retail market, and local players have enjoyed a dominant position driven by formulation development capabilities and early investments. While the Indian pharmaceuticals market ranks 10th globally in terms of value, it is ranked 3rd in volume of pharmaceutical products. McKinsey estimates that the Indian pharmaceutical market was valued at $12.6 billion in 2009 and expected to reach $100 billion by 2025 for Indian Brand Equity Foundation.

The Association of Biotechnology Led Enterprises estimates that India’s biologics market will grow at a compound annual growth rate (CAGR) of 22 percent to hit $12 billion by 2025. India approved its first similar biologic in early 2000, prior to the European Union in 2006 and the United States in 2015. Today, India is one of the leading manufacturers of similar biologics, and there is a thriving domestic market with 93 total products approved through 2019; low cost of research and development has promoted the increased development of similar biologics in the country.

Amit: With growing demands for quality pharmaceuticals, both biologics and small-molecules, the Indian government is also taking steps to support the life science industry with the necessary infrastructure, funding, and global collaborations. Between public and private sector growth in the region, Avantor is well-positioned to continue to be part of this growth and continue to work closely with the biotechnology and pharmaceutical companies developing and manufacturing a wide variety of life-altering therapies that will improve global health.

What are the major plans in store for the FY21 for India? How much growth is expected?

Amit: Avantor is well-positioned with the capabilities and expertise to be a key solutions provider for biotechnology and pharmaceutical customers globally. Our manufacturing, R&D and distribution footprint enables us to serve nearly a quarter of a million customer locations around the world, and our offering of more than 6 million products, a combination of our own plus those of our supplier partners, deeply embed us in our customer workflows.

India is an important market for us. We are among the top companies supporting leading biologics and vaccines manufacturers. We also support small molecules manufacturing and testing, research and academics, and in vitro diagnostics.

Narayana: Our manufacturing facilities in Panoli (Gujarat) and Dehradun (Uttarakhand) are providing world-class pharmaceutical excipients and diagnostics products to customers in India and abroad. We are rapidly expanding our capacity at these facilities to meet existing and future market needs. And our recent acquisition of RIM Bio in Changzhou, China, adds another critical footprint for us in the region, specifically dedicated to the growing area of single-use manufacturing, to serve India and the entire AMEA region.

Amit: Throughout the pandemic, we have supported our customers in improving the speed of response through our range of products suitable in the workflow of COVID-19 detection, safety and treatment. Recently, our COVID-19 RT-PCR testing Universal Transfer Media (UTM) kits have won acceptance and positive feedback from both public health agencies and private health care providers.

Please share the company's plans for India for the coming years.

Amit: Avantor has been in India for 30 years now. Locally, over 2,000 employees provide products and technical support to our customers in healthcare alone as we continue to scale up our manufacturing capacity and bring in new products to meet the requirements of the Indian life sciences market.

Narayana: The relevance and criticality of the life sciences sector has been highlighted more than ever by the COVID-19 pandemic: the exponential rise in COVID-19 cases has resulted in the need for solutions in prevention, screening and treatment. Since the onset of the pandemic, our offerings have ranged from relatively simple solutions like masks, gloves to sophisticated cGMP production materials and single-use technologies used in vaccines.

Amit: It is worthwhile to mention that one of our biggest vaccine customers appreciated and highlighted our team as partners because of the on-time development and delivery of materials needed for their COVID- 19 vaccine development, despite lockdowns and slowing of global supply chains on account of the pandemic.

We will continue to focus on India as one of our key markets by expanding our local manufacturing capacities, increasing our employee base, and bringing in unique solutions that meet the needs of our customers in the region. We aim to bring in more investments for our local manufacturing capabilities to support the Indian government’s initiative of “Make in India”.

Dr Manbeena Chawla

(manbeena.chawla@mmactiv.com)