Adding value to government’s mandated QR code on all APIs

December 21, 2022 | Wednesday | Views | By Santosh Narayanan BT, Senior Business Analyst Consulting, Navitas Life Sciences

A decisive step towards building effective measures against spurious drugs

One of the definitive ways of ensuring drug safety is by building robust and consistent measures to prevent substandard quality. As a measure to accomplish this, government of India (GSR20(E)) has mandated that a QR code be affixed to all Active Pharmaceutical Ingredients (APIs) manufactured or imported to India. The requirement will come live from 1st January 2023.

The mandate has been brought in as an effort to combat the issue of counterfeit medicines in India. According to available statistics, up to 20% of drugs manufactured in India are counterfeit, and, as per a government report, up to 3% of manufactured drugs are of substandard quality.

Globally, serialisation efforts are in place for finished goods wherein the saleable units, and the packaging has a unique serial number associated with them to identify the product and provide traceability.

India’s QR Code Mandate:

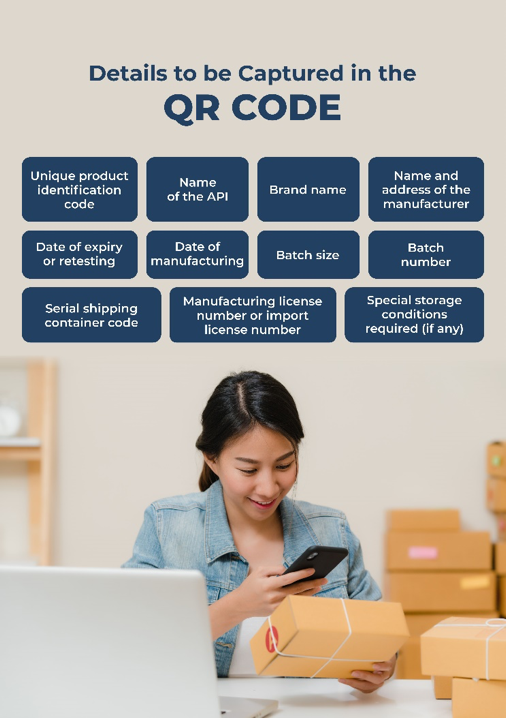

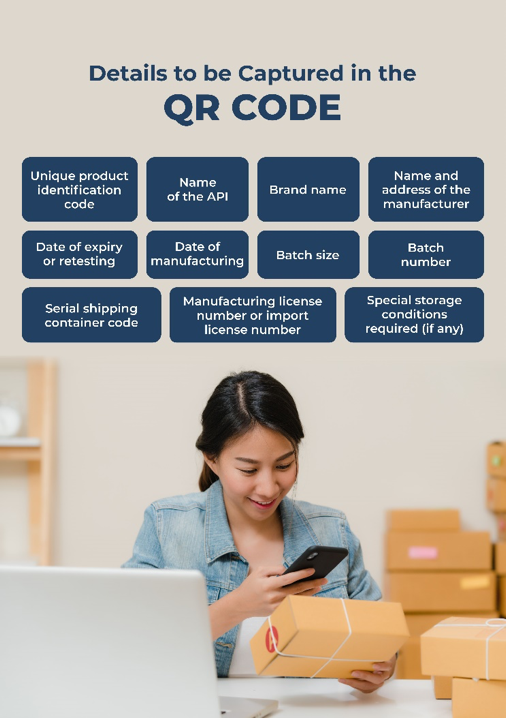

This mandate introduces serialisation labeling at an API level before the formulation of drugs, and this applies to all API manufacturers who manufacture or export API to India. The QR code needs to capture essential data which would enable traceability.

Essentials of Scanning Support

The mandate also includes a scanning requirement. The scanning application should maintain the capability to scan and parse the barcode data encoded within the QR.

The manufacturer will now have the capability to create the QR code and the scanning/decoding capability as well. However, a scanner would also be required by the next receiver within the product’s supply chain to scan and parse the QR code. This would aid in verifying the information, resulting in an indirect spill over where the receiving organization will need scanning capabilities as well. The real takeaway is that these changes signal the likely introduction of end-to-end traceability.

Holistic Growth Blueprint: Essential aspects to Managing the Challenges

The implementation of a solution that aids in compliance brings with it its own challenges. To adhere to this requirement and to follow a holistic growth blueprint, it is important to follow 5 core elements:

- Integration into existing systems: Manufacturers should look into the question whether to invest in the existing setup or build an integrated solution which can withstand future regulatory extensions. Any proposed solution should add on to the existing business use cases and business practices for user adaptability and a smooth transition.

- Generation of a Serial Shipment Container Code (SSCC): The SSCC is generated using an EPCIS (Electronic Product Code Information System) repository, which is typically used during the drug serialization process. Big pharma manufacturers would have an EPCIS repository but the mandated QR code requirement could introduce many mid to small pharma manufacturers to SSCC. It will be important for mid-sized or small manufacturers to subscribe to a serial number manager to generate the SSCC labels. A validated hosted/on-premise solution that can accommodate the specific requirement and is able to handle further upgrades in terms of regulatory requirements is a necessity.

- Data Accessibility: Another consideration in implementation is with respect to data availability. While the manufacturers will have required data, it is spread across multiple applications. The challenge is in making the data available for a solution to pull in the information.

One of the key constraints is that the data though available, needs to be retrievable with ease to suffice current regulation. The ERP systems used by the manufacturers maintain majority of the required data, but the challenges are in integration with the solution software to automatically pull the required data and at the same time, work with the business on any business flows. Integration is a challenging task. Remember, the deadline is the First of January 2023. With the impending requirement timeline, a robust and scaleable solution, which can work hand in hand with your existing business processes in sufficing requirements as stated in GSR20(E) will help.

- Labelling Solution: Current businesses have existing product templates based on product, shipment size, customer requirements etc. Any labeling solution would work best if the application works with current business templates rather than introducing a new label set.

Also, from an audit perspective, there should be provisions to include transactional data. This data contains information on labels printed, product/batch, links to the customer, and more. Implementation Flexibility is the key.

- Seamless Implementation: Any solution should include a phase wise implementation plan. The solution on the short term should focus on addressing the regulatory compliance requirements within the stipulated timelines. However, the solution framework should be dexterous to support integration with backend systems. This will ensure that the data flow does not remain dependent on manual inputs and can sustain with the required systems for pull/push of data.

Essentially a solution approach which provides the market with an implementation agility to move from a standalone to an integration model will serve long term dividends.

What is required is a device independent application that can interface with a wide variety of ERP, non-ERP, and custom solutions. Pharmaceutical industries are constantly looking for ways to ensure compliance through highly efficient and consistent processes. A perfect solution that is a critical driver of enhanced day-to-day operations, elevating the product development phase, and meeting the challenges of stringent regulations is needed.

Digital integrations that have a clear and upfront strategy can empower pharma manufacturers to develop the right strategies. The QR code mandate by the government of India is a decisive step towards building effective measures against spurious drugs. An established solution will facilitate faster and value added compliance.

Santosh Narayanan BT, Senior Business Analyst Consulting, Navitas Life Sciences