Will Indian pharma embrace batch to continuous processing?

November 20, 2015 | Friday | News

Will Indian pharma embrace batch to continuous processing?

(Photo Courtesy: www.wsj.com)

STEERLife, incubated since 2013 and rolled- out as an entity in April 2014, is run by MD & chief knowledge officer, Dr Babu Padmanabhan, and chairman Dr Himadri Sen (former research head at Ranbaxy), and has an ambitious goal of reaching the Unicorn status by 2020.

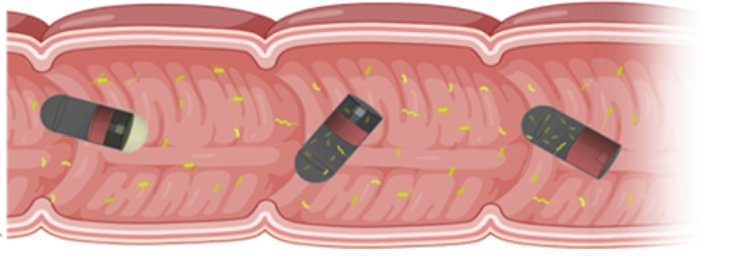

The start-up aims to revolutionize the pharmaceutical industry by changing the way medicines are 'made' and 'taken', i.e., to transition from the conventional batch process manufacturing practice to continuous processing (B2C); and from swallowing-to-sipping medicines.

The traditional batch processing involves multiple steps including blending, wet granulation, drying, milling, compression and coating.

After each of these steps, the product (semi-batch) is collected, quality checked, and then is put through the next process of operation before ending up as a finished product, thereby making the whole process very cumbersome, inefficient, and time-consuming causing environmental hazards.

Currently, the pharmaceutical industry employees batch processing method, which is as old as Industrial Revolution, leading to producing products of inconsistent quality, paving way for pharma facilities and manufacturing plants being written-off or shutdown owing to defects, contaminations, or improper testing.

"The manufacturing process adopted by the pharma industry is similar to that of mixing cement and sand to make concrete blocks. In batch processing, it takes several hours with repeated handling and testing of the batch. However, with continuous process, it reduces to anywhere between 3 to 30 seconds. It is a greener technology," said Dr Padmanabhan, while talking to the media at a press conference in Bangalore on November 19, 2015.

Dr Janet Woodcock, director, Center for Drug Evaluation and Research (CDER), United States Food and Drug Administration (USFDA), commented at an American Association of Pharmaceutical Scientists (AAPS) annual meeting in 2011, "Right now, manufacturing experts from the 1950s would easily recognize the pharmaceutical manufacturing processes of today. It is predicted that manufacturing will change in the next 25 years as current manufacturing practices are abandoned in favor of cleaner, flexible, more efficient continuous manufacturing."

Right now there are no specific regulations and guidelines for continuous manufacturing or for prohibiting it.

Dr Sen said that the USFDA will force the pharma industry to adopt the continuous manufacturing process. "The USFDA will be a facilitator and will request the industry to change from quality-by-testing (QbT) to quality-by-design (QbD)," he added.

Advantages of continuous processing include better quality, energy efficiency, lesser waste management and more greener towards the environment.

STEERLife's technologies include Hot Melt Extrusion (HME), Hot Melt Fragmentation (HMF - patent pending), and Activated Granulation.

The company's another patent-pending Effervescence Technology (EVT) looks to transform the traditional swallowing of pills to sipping it.

Pharma companies can now extend their patents for 3 additional years through introducing the same USFDA-approved drug in a different dosage format, i.e., as effervescent tablets, which is sipped after dissolving in water. Introduction of drugs in a different dosage form is considered as 'dosage innovation'.

Generally, the USFDA expects pharma companies to introduce their same approved drugs for Geriatric (older adults) and Pediatric (children) patients in easily ingestible dosage forms. However, companies abandon that option owing to higher cost of production.

Dr Sen revealed that the company first intends to introduce its processing technology to MNCs in the US than to Indian companies.

The company's development center in India is located in Bangalore due to high costs involved in the US. In India, the R&D costs is about one-fifth to that of the US.

The technology has been developed at its Bangalore development center.

An investment of Rs 7-10 crore (US $1.5-2.0 million) has gone into STEERLife through internal approvals within the company.

STEERLife so far has been in talks with 4 Indian MNCs and 1 foreign MNC for implementing its technology.

The company also targets other industries including nutraceuticals and beverages for implementing its processing technology.

It has filed 3 patents which are at various stages in the application process. It usually takes 1.5-2 years for granting a patent.

Mr Dipak Chattaraj, ex-chairman of Ranbaxy USA, serves as STEERLife's advisor, and Mr Indu Bhushan as chief technology officer (CTO).

Established in 1993, STEER Group creates advanced materials platform technologies for the plastics, pharma, food & nutraceuticals, biomaterials and biorefining industries.

It has 5 global offices, 10 satellite offices and 3 application development centers, and employs over 500 professionals.