IIT-M identifies alternative method for producing anti-cancer drug Camptothecin

February 25, 2021 | Thursday | News

Developed a microbial fermentation process that can be an economically efficient and sustainable method of production to fulfil the market demand at large scale

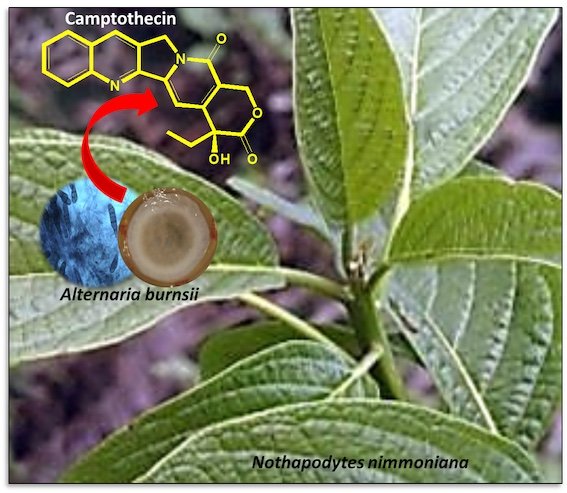

IIT Madras (IIT-M) Researchers have now developed an alternative method of Camptothecin production to meet the demand and conserve the natural sources. To this effect, they developed a microbial fermentation process that can be an economically efficient and sustainable method of production to fulfil the market demand at large scale.

The research was led by Dr Smita Srivastava, Associate Professor, Department of Biotechnology, IIT Madras. This work was recently published in the reputed peer-reviewed international Journal of Scientific Reports (a Nature Research Publication).

Highlighting the applications for this research, Dr Srivastava, said, “The novelty of the work lies in the fact that unlike other potential microbial strains reported, this strain has been found to show sustainable production even beyond 100 generations. The plan now is to use the isolated novel strain for the development of a microbial fermentation based sustainable bioprocess for large scale in vitro production of Camptothecin, preferably in collaboration with interested Industrial partner(s).”

Prof Suresh Kumar Rayala, Department of Biotechnology, IIT Madras, said, “Preliminary investigations on breast cancer, lung cancer, ovarian cancer and colorectal cancer cell lines revealed that the microbial extract demonstrates a potent cytotoxic effect on lung cancer (H1299), ovarian cancer (SKOV3) and colorectal cancer (HT29; Caco-2) cell lines, comparable to the standard Camptothecin.”

Khwajah Mohinudeen, IIT Madras PhD Research Scholar who worked on this study, said, “Researchers from the Plant Cell Bioprocessing laboratory at IIT Madras have been able to successfully isolate the highest-yielding strain of Camptothecin reported to date with sustainable production up to reactor level. In addition to isolating a novel microbial source for bioprocess development for the large scale production of Camptothecin, we have also come up with a rapid screening technique for isolation of high Camptothecin yielding microbial strains from plants.”