"We want our tech-enabled innovations to help individuals and industries"

November 02, 2021 | Tuesday | Interviews

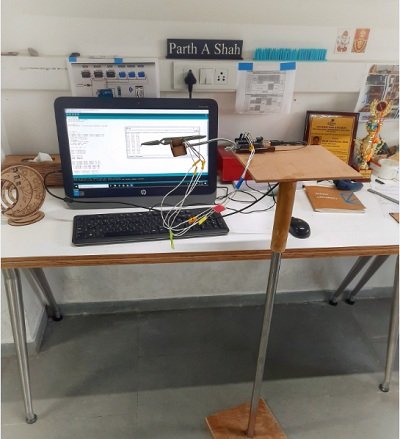

Makerspace at Ahmedabad-based Anant National University has been instrumental in providing students with a facility where ideas can be converted into real products and artefacts. Recently, scientists from the institute have worked on devices for dentist implant orientation and Smart Chair. Parth Shah, Assistant Professor School of Design - AnantU reveals more in interaction with Bio Spectrum India

Recently Makerspace at Anant National University has worked on devices for dentist implant orientation and Smart Chair. Tell us more about the innovations?

Smart bamboo chair: Countless people are spending many hours on a desk job. Adding further, the work from home culture has changed the routine movement in offices into sitting continuously and viewing a screen without any option. This has overall led to various health issues emerging due to wrong sitting postures. This is where the objective of the Smart Bamboo Chair is to minimise the health complications by buzzing a sound, which will signal the person to fix his way of sitting – basically correcting the wrong posture. In the chair, an ultrasonic sensor is fixed at the backside of the chair, which will sense the signal and the distance of the human back. If the human posture is not accurately measured, the controller will give the signal and send the data to the buzzer. Any increase in the distance indicates bending of the back. The projects have been developed by me.

Dental implant: Dental brackets are temporary implants on teeth anchored on which the braces pull teeth into alignment. However, each tooth that needs correction has a different alignment, and so the anchor bracket needs to be positioned at the correct angles in all three axes for best results. Currently, this is done manually and involves a great deal of the dentist's judgement, and accuracy is not very high, with margins of error of 3 to 6 degrees depending on the dentist's experience. A dental implant aims to recorrect that.

Makerspace is a Hi-tech Lab, a place where you can convert ideas into reality. Equipped with a complete set of Arduino boards and supported accessories with sensors and actuators, Makerspace at AnantU makes it possible to invent, create, and tinker at Anant National University. The digital manufacturing capability includes 3d printing, laser cutting and etching, and a full 8’x4′ CNC routing with the electronics workbench.

What type of technology was used to work on the innovations?

The smart bamboo chair is connected through an Arduino Uno Controller Board and Distance sensor. In the case of the dental implant, in this system, we have used the Arduino controller, which will receive the signal in the form of voltage and that voltage will be converted into angular position using the Acceleration Sensor ADXL335, which will be interface with the controller board. The results can be displayed on the serial monitor screen.

Are there plans to patent the products?

Undoubtedly these technologies are unique with several first-timer products in India. However, we have not planned yet for filing any patents for the mentioned projects. We want our tech-enabled innovations to help individuals and industries, rather than thinking one-sided.

How much fund was accrued for the dental implant orientation programme?

A total of Rs 40000 was accrued for the dental implant orientation programme.

Any plans to market the products?

As mentioned above, we are not looking at our products from any commercial angle and hence, no such plans to market the products.

How many students are associated with the programme?

The dental implant project was our faculty consulting project with Dr Alka Banker (Orthodontics) and Milind Chitale - the Director Makerspace, and myself. In the case of the Smart Chair Project, it is developed by me.

On which other projects will Makerspace work?

Makerspace is working on several projects; the ongoing ones include - the crops monitoring system, Aquarium Automation Using IoT, Affordable automatic pet feeder, Foucault pendulum & IoT-Based Solar Panel Monitoring System for Safety and efficiency.

Sanjiv Das

sanjiv.das@mmactiv.com